Heatless

Heatless Desiccant Dryers

PH heatless adsorption dryers use dry, expanded purge air to remove moisture from the desiccant material. Incorporating high-quality components, PH heatless desiccant dryers provide you with clean, dry air to extend the life of your equipment and products. Heatless desiccant dryers use the compressed air to remove any moisture from the desiccant material.

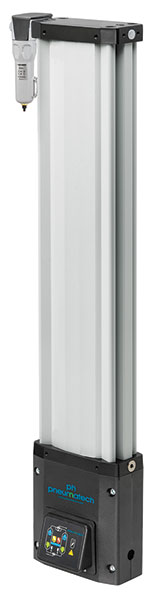

PH 2-45 HE

Incorporating high-quality components, PH heatless adsorption dryers provide you with clean, dry air to extend the life of your equipment and products. Heatless adsorption dryers use dry, expanded purge air to remove moisture from the desiccant material.

PH 2-45 HE adsorption dryers are capable of drying air to a PDP of -70°C/-94° F, simply by reducing the flow, thanks to the use of carefully selected molecular sieves. The desiccant is housed in a robust extruded aluminum body, which can operate until 16 barg/232 psig (fatigue load). The dryers are equipped with a mounted pre-filter and an integrated after-filter as standard, can be installed vertically and can also be wall-mounted with a specially designed wall-mounting kit (optional).

The controller ensures the lowest operational costs thanks to compressor synchronization and the optional PDP control. LED’s on the controller indicate whether power supply is connected, towers are pressurized and solenoids are functioning properly. It also provides with preventive maintenance information. Alarms can also be triggered remote thanks to the available voltage-free contact.

Benefits

- Advanced energy management for lowest operating costs

– Compressor synchronization

– Purge nozzle optimization (optional)

– PDP control (optional) - High-quality, high-efficient desiccant, selected for the right application – molecular sieves

- Spring-loaded cartridges, hence minimizing the risk of crushed desiccant

- Counter-current regeneration for optimal energy efficiency and guaranteed dry air

- Designed for transportability & mountability

- Dryer can be installed vertically or horizontally

- Wall-mounting kit (optional)

- In & outlet can be reversed

- Low noise levels while purging

- High reliability and robust design

PH 45-690 HE

The Pneumatech PH HE adsorption dryer has always earned its High-Efficiency label. Its new models with structured desiccant take these energy savings to a new level. In fact, thanks to their groundbreaking solides desiccant, the newest additions to the PH HE range offer the lowest total cost of ownership on the market. They also set new standards in reliability, low maintenance requirements and versatility for truly superior dryer performance.

Benefits:

- Structured desiccant offers highly efficient air flow and regeneration

- Stable low pressure dew point 40% longer desiccant lifetime

- Easy desiccant maintenance

- No desiccant dust that can cause dryer failures and compromise production

- Pneumatic valves add robustness in demanding environments

- Vertical or horizontal installation

- Purge nozzle optimization PDP control (optional for DC1 controller)

- Wall-mounting kit (optional for Simplex models)

PH 55-550 HE

Incorporating high-quality components, PH heatless adsorption dryers provide you with clean, dry air to extend the life of your equipment and products. Heatless adsorption dryers use dry, expanded purge air to remove moisture from the desiccant material.

PH 55-550 HE adsorption dryers are available in 3 PDP variants:

-20°C/-4°F , -40C0/-40°F and -70°C/-94°F, each optimized to provide the lowest purge loss. The unique manifold (patent pending) includes pilot air controlled 3/2-way valves, which switch fast and reliably. The pressure drop over the valves is reduced to a minimum. This does not only result in a low pressure drop over the dryer, but also ensures maximum purge air expansion during regeneration. The latter makes that the purge consumption of the dryers has been reduced significantly.

The desiccant is spring-loaded and housed in a robust extruded aluminum body, which can operate up to 14 barg/203 psig (fatigue load). The dryers are equipped with a mounted pre-filter and after-filter as standard and can also be wall-mounted with a specially designed wall-mounting kit (optional).

Operating costs are optimized at all times thanks to the availability of compressor synchronization and purge nozzle optimization as standard and PDP control as option. The full machine status can be checked on the display of the controller and the vessel pressure gauges on the unit.

The controller indicates whether power supply is connected, towers are pressurized, valves are functioning properly or preventive maintenance needs to be done. In case the optional PDP control is connected, the PDP value can monitored from the display. Alarms and warnings can also be triggered remote with the available voltage-free contacts.

Optionally the Purelogic™ can be used as central brain of the adsorption dryer.

The PurelogicTM offers impressive control and monitoring capabilities, and can communicate with industrial protocols as Modbus, Profibus or Ethernet/IP.

Benefits:

- Advanced energy management for lowest operating costs

– Compressor synchronization

– Purge nozzle optimization

– PDP control (optional) - Best-in-class performance thanks to (patent pending)

– Lowest pressure drop during drying

– Lowest purge loss by ensuring maximum purge air expansion during regeneration - Low noise levels during purge and blow-off

- High-quality, high-efficient desiccant, selected for the right application

– PDP -20°C/-3°F & PDP -40°C/-40°F: activated alumina

– PDP -70°C/-94°F: molecular sieves - Spring-loaded desiccant, minimizing the risk of crushing

- Counter-current regeneration for optimal energy efficiency and guaranteed dry air

- Designed for transportability & mountability

– Wall-mounting kit for PH 55-190 HE (optional) - Optimal control and monitoring thanks to the Purelogic™ controller (optional)

- Desiccant bags for easy service from the top

PH 55-550 S

Incorporating high-quality components, PH heatless adsorption dryers provide you with clean, dry air to extend the life of your equipment and products. Heatless adsorption dryers use dry, expanded purge air to remove moisture from the desiccant material.

PH 55-550 S adsorption dryers are available in 2 PDP variants:

-20°C/-4°F and -40C0/-40°F.The unique manifold (patent pending) includes pilot air controlled 3/2-way valves, which switch fast and reliably.

The desiccant is spring-loaded and housed in a robust extruded aluminum body, which can operate up to 14 barg/203 psig (fatigue load). Pre- and afterfilters are delivered as standard with every dryer.

Operating costs are optimized at all times thanks to the availability of compressor synchronization and purge nozzle optimization as standard and PDP control as option. The full machine status can be checked on the display of the controller and the vessel pressure gauges on the unit. The controller indicates whether power supply is connected, towers are pressurized, valves are functioning properly or preventive maintenance needs to be done. In case the optional PDP control is connected, the PDP value can monitored from the display. Alarms and warnings can also be triggered remote with the available voltage-free contacts.

Benefits:

- Advanced energy management for

– Compressor synchronization

– Purge nozzle optimization (2 nozzles)

– PDP control (optional) - High reliability and low maintenance costs thanks to unique valve design (patent pending)

- High-quality desiccant, resulting in a consistent PDP of -20°C/-3°F or -40°F/-40°F

- Spring-loaded desiccant, minimizing the risk of crushing

- Counter-current regeneration for optimal energy efficiency and guaranteed dry air

- Designed for transportability & countability

– Wall-mounting kit for PH 55-140 S (optional) - Advanced controller to monitor machine status at all times

- Desiccant bags for easy service from the top

PH 65-3390 S

Pneumatech has been manufacturing energy-efficient desiccant dryers for nearly 50 years. We are proud to introduce this new design heatless desiccant dryer with low pressure drop, improved controls, compact design and many other features you have come to expect from Pneumatech.

The PH 65-3390 S (standard) is a reliable product with an attractive value. If you are in need of more features and options, Pneumatech offers the PH version in a high efficiency (HE) version as well.

Benefits:

- Flanged larger diameter robust vessel (welded vessel)

- Screens and vessels can be inspected and cleaned

- Resume cycle where it stopped, avoiding bed saturation

- Status functionality on the controller

- Lifting eyes and forklift slots for easy installation

- Remote alarms (free contact)

- Load/unload contact (if wired, stops unit when compressor unloads)

- Large pneumatic line filter as standard

PH 760-3390 HE

Pneumatech presents the newly designed and significantly improved heatless adsorption dryer range – PH 760-3390 HE. Incorporating high-quality components, PH heatless adsorption dryers provide you with clean, dry air to extend the life of your equipment and products. Heatless adsorption dryers use dry, expanded purge air to remove moisture from the desiccant material.

PH 760-3390 HE adsorption dryers are capable of drying air to a PDP of -40°C/-40°F as standard and -70°C/-94°F as option for higher flows up to 5760 m3/hr/3390 cfm. The desiccant is housed in welded vessels, which are coated and can operate up to 9 barg/130 psig (fatigue load) with std variant and up to 14,5 barg/203 psi with high pressure variant(fatigue load). All dryers can be equipped with 2 coalescing pre filters before and 1 particulate filter after the dryer (optional).

Thanks to ingeniously designed mechanical components i.e open type of silencers and large vessels, PH 760-3390 HE range offers highest performance with lowest pressure drop and improved purge loss of 16%.

Considering different needs of the customers, the PH 760-3390 HE range offers 3 different controller for different requirements. DC 1 Controller version has a basic controller with required controls and monitoring such as Service Alarm, General alarm relay, synchronization control and optional dew point control whereas Purelogic™ controller version will have the Purelogic™ as central brain of the adsorption dryer.The Purelogic™ optimizes operating costs; ensures maximum reliability by monitoring the most important parameters; and offers impressive control and monitoring capabilities. For special applications where Pneumatic control is preferred and no electricity is possible, PH 760-3390 HE also operates with Pneumatically enabled controller.

Benefits

- Available in three standard variants

– With Standard DC1 Controller (PDP Control optional)

– With Purelogic™ (PDP control std available)

– With Pneumatic Controller (no need of electricity for the installation and no PDP control possible) - Lowest possible pressure drop thanks to innovative open silencer design

- Improved performance with reduced purge rate to 16% across the complete range

- Advanced energy management for lowest operating costs

– PDP control – (std with Purelogic™ and optional with DC1 Controller)

– Compressor synchronization

– Purge nozzle optimization (optional) - High-quality, high-efficient desiccant, selected for the right application

– PDP -40°C/-40°F (std): activated alumina

– PDP -70°C/-94°F and high inlet temp. (option): molecular sieves - Minimal risk of crushed desiccant thanks to the large vessel diameter and the sonic nozzle (std available)

- Counter-current regeneration for optimal energy efficiency and guaranteed dry air

- High reliability and robust design

- Low noise levels while purging

- Designed for transportability

- Optimal control and monitoring thanks to the Purelogic™ controller

Contact us for more information about

Heatless Desiccant Dryers

By joining our mailing list you are agreeing to our Privacy Policy